The Flexible Vision-Based Placing Machine is a compact, high-precision desktop device that uses vision guidance and a robotic arm to intelligently sort and place small, irregular parts.

| Weight | 80 kg |

|---|---|

| Dimensions | 400 × 600 × 886 mm |

| Model | LBM-SXY-208-1 |

| Accuracy | ±0.1 mm |

| Applicable Product Size | 5 mm – 30 mm |

| Vibration Plate Size | 200 × 150 mm |

| Air Pressure Requirement | 0.4 – 0.6 MPa |

| Voltage | 220V |

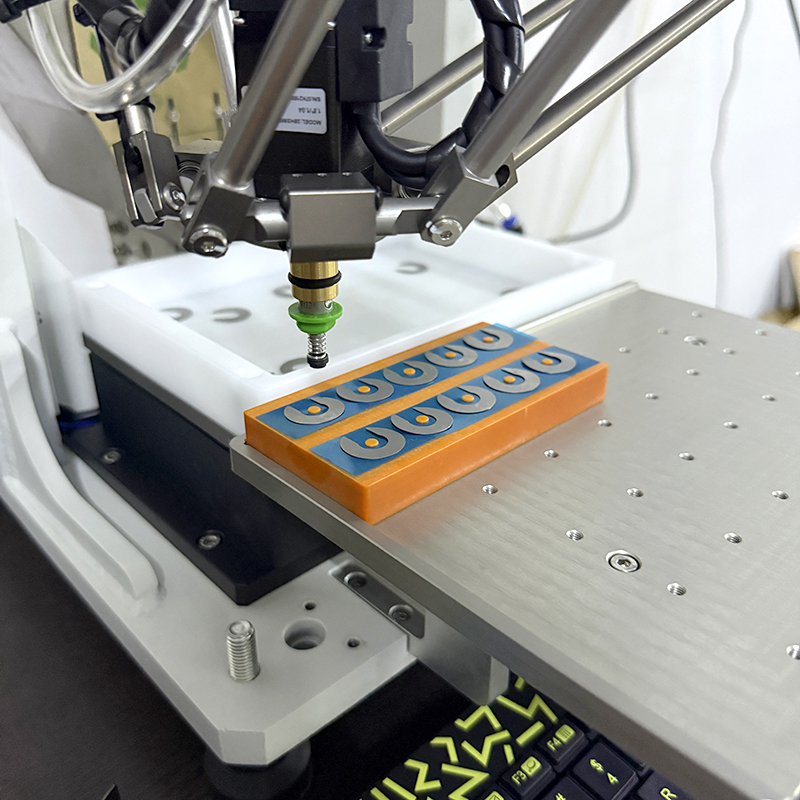

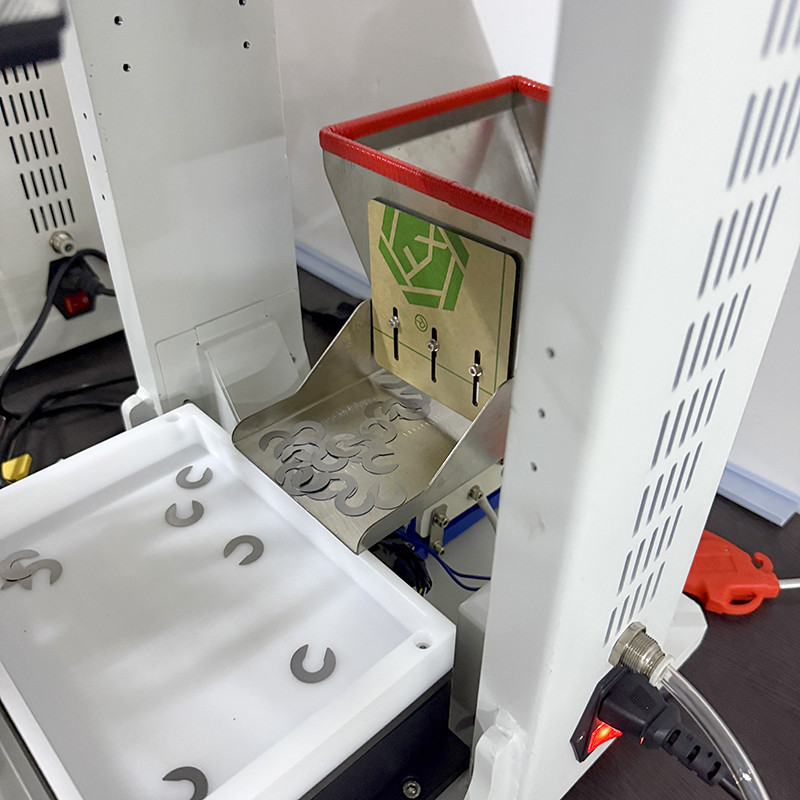

The Flexible Vision-Based Placing Machine (Model: LBM-SXY-208-1) is a compact, high-precision desktop automation solution designed to intelligently sort and arrange small parts during production. Engineered with a visual recognition system and a robotic arm similar to an octopus in structure, this machine excels in automating the feeding and placement of irregular or unordered products. Featuring a flexible material supply mode and responsive adaptation to production changes, it significantly improves productivity, ensures precise part positioning, and reduces labor costs. Its intelligent vibration system ensures smooth separation of overlapping parts for optimal pick-and-place efficiency.

| Item | Specification |

|---|---|

| Model | LBM-SXY-208-1 |

| Accuracy | ±0.1 mm |

| Machine Dimensions | 400 × 600 × 886 mm |

| Weight | 80 kg |

| Vibration Plate Size | 200 × 150 mm |

| Applicable Product Size | 5 mm – 30 mm |

| Air Pressure Requirement | 0.4 – 0.6 MPa |

| Voltage | 220V |

| Power Consumption | 500W |

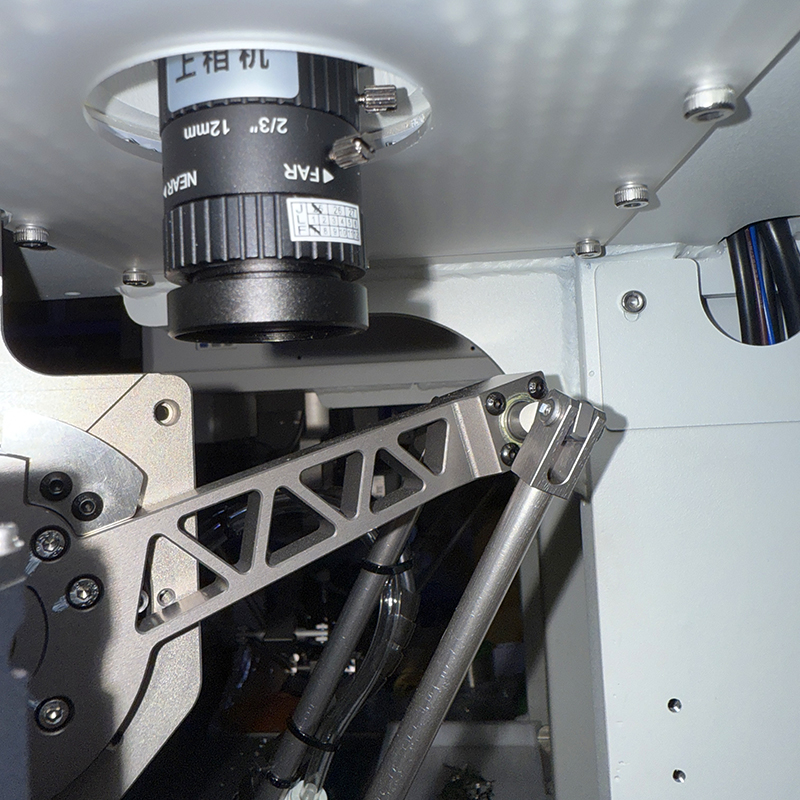

Vision-Guided Precision: Integrated industrial camera captures part positions and guides the robotic arm for accurate placement.

Octopus-Style Manipulator: Multi-joint mechanical arm with suction head ensures stable gripping and precise positioning.

Flexible Feeding System: Supports different product shapes and sizes, and vibrates when parts overlap to ensure smooth separation.

Space-Saving Design: Compact desktop footprint ideal for constrained workspaces.

Stable & Efficient: Reduces manual errors and speeds up sorting and assembly processes.

Intelligent Response: Quickly adapts to changing production requirements and varying part configurations.

The LBM-SXY-208-1 Flexible Vision-Based Placing Machine is ideal for industries requiring high-precision part handling, such as:

Electronics: Automated placement of small electronic components.

Medical Devices: Precision sorting of small, delicate parts.

Precision Hardware: Assembly line feeding and pre-arrangement of miniature mechanical parts.

Automation Lines: Serves as a pre-feeding or sorting station to streamline downstream processes.

LabeMachine is a specialized manufacturer of labeling machines and complementary equipment. Our main products include wire labeling machines, bottle labeling machines, flat labeling machines, packaging machines, and filling machines. We are committed to providing high-quality, reliable solutions for all your labeling and packaging needs. more+

WhatsApp us

Our services use cookies to improve your experience. By continuing to use our services, you consent to the use of cookies. learn more