Manual liquid packaging is time-consuming, error-prone, and inefficient for large-scale production, leading to production delays and inconsistent product quality. This can result in dissatisfied customers and financial losses. Automatic liquid packaging machines offer a solution with speed, precision, and scalability to meet modern production needs effectively.

An automatic liquid packaging machine is an advanced system designed to automate the filling, sealing, and packaging of liquid products. It increases production efficiency, ensures precision, and minimizes waste, making it ideal for industries such as food, beverages, and pharmaceuticals.

Discover how these machines can revolutionize your operations with their innovative features and industry-wide applications.

Understanding Automatic Liquid Packaging Machines

Automatic liquid packaging machines are specialized devices designed to handle various liquid packaging tasks, such as filling, sealing, and labeling. These machines streamline processes by automating repetitive tasks, improving production speed, and reducing human error.

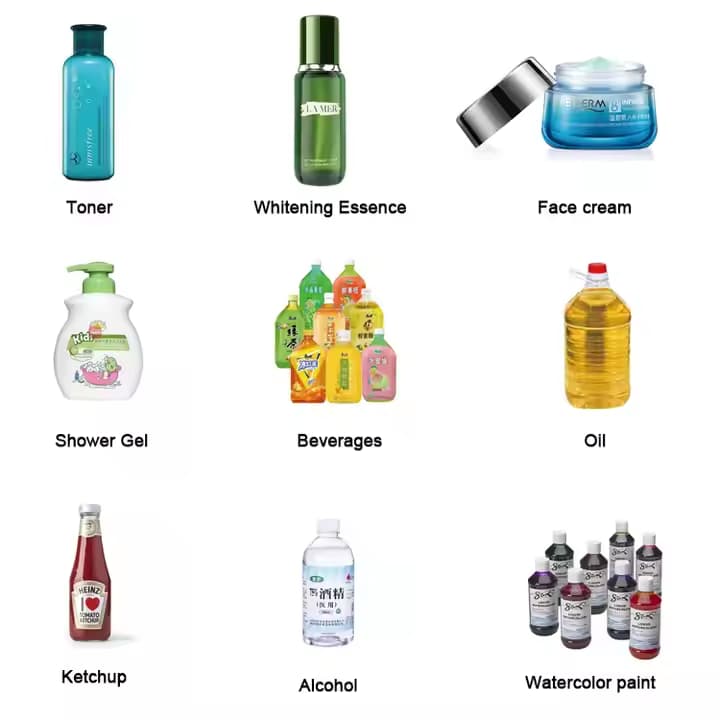

They are widely used in industries like food and beverage, pharmaceuticals, and cosmetics. From bottled water to liquid medicines, these machines provide efficient solutions for high-volume packaging demands.

Core Functions of Automatic Liquid Packaging Machines

Filling

Automatic liquid packaging machines utilize advanced systems to fill liquids into containers with precision. They accommodate various liquid types, from water-like fluids to viscous substances such as syrups or lotions.

Sealing and Capping

Sealing ensures product hygiene and prolongs shelf life, while capping secures the container, preventing spillage. Machines can handle diverse closure types, from screw caps to induction sealing.

Labeling

Integrated labeling systems such as flag labeling machines or industrial label printers ensure accurate and professional product presentation, vital for branding and regulatory compliance.

Types of Automatic Liquid Packaging Machines

Liquid Filling Machines

These machines cater to different liquids, employing piston, gravity, or vacuum systems based on viscosity. They are suitable for everything from water to oils and sauces.

Sachet Packaging Machines

Designed for single-use liquid packs, sachet machines are popular for products like juices and shampoos. They efficiently form, fill, and seal pouches.

Bottle Filling Machines

These machines specialize in filling rigid containers like bottles. Commonly used in beverages and cleaning industries, they are often paired with bottle capping machines.

Key Components of an Automatic Liquid Packaging Machine

- Filling Mechanism: Ensures accurate liquid volume in each container.

- Conveyors: Transport containers smoothly through the packaging stages.

- Sealing Units: Create airtight closures for product preservation.

- Labeling Systems: Apply accurate labels using techniques like flat labeling or corner wrap labeling.

Advantages of Using Automatic Liquid Packaging Machines

- Efficiency: Accelerate production speeds with minimal supervision.

- Precision: Deliver consistent filling and sealing results.

- Cost Savings: Reduce material waste and operational costs.

- Scalability: Adjust production capacity to meet growing demands.

Challenges and Considerations

While these machines offer significant benefits, their initial investment can be high. Maintenance and training for operators are crucial to avoid downtime and ensure optimal performance. Additionally, the machine type must align with the liquid’s viscosity and packaging requirements.

Common Industries and Applications

- Food and Beverage: Packaging liquids like sauces, juices, and dairy products.

- Pharmaceuticals: Filling liquid medications and supplements.

- Cosmetics: Bottling lotions, serums, and oils.

Trends in Automatic Liquid Packaging

Modern machines incorporate IoT for remote monitoring and diagnostics, energy-efficient designs, and customization options for niche packaging needs. For example, integrating a vacuum packaging machine can enhance product preservation in industries requiring sterile packaging.

How to Choose the Right Machine for Your Needs

- Product Type: Assess liquid viscosity and container style.

- Production Volume: Evaluate the machine’s capacity to meet production goals.

- Additional Features: Look for integrated systems like barcode printers for streamlined operations.

Future of Liquid Packaging Machines

The future of automatic liquid packaging machines is promising, with innovations such as AI-driven maintenance, enhanced safety standards, and tailored solutions for emerging industries. Automation will continue to drive efficiency and quality across the packaging sector.

Conclusion

An automatic liquid packaging machine ensures precision, efficiency, and scalability, making it an essential asset for industries aiming to optimize their production processes.