Tube labeling machine belongs to one kind of flag labeling machine classification, we usually name the machine according to the field or product it is used. If your product belongs to the tube or hose category and you need to label it, then this article can help you understand how to buy a suitable tube labeling machine.

To choose the right tube labeling machine, consider factors like the type of tube, production volume, and budget. Investing in a reliable machine will enhance efficiency and ensure consistent labeling quality.

Finding the best machine can be challenging, but don’t worry, I’ve got some insights to help you out.

Understanding Tube Labeling Machines

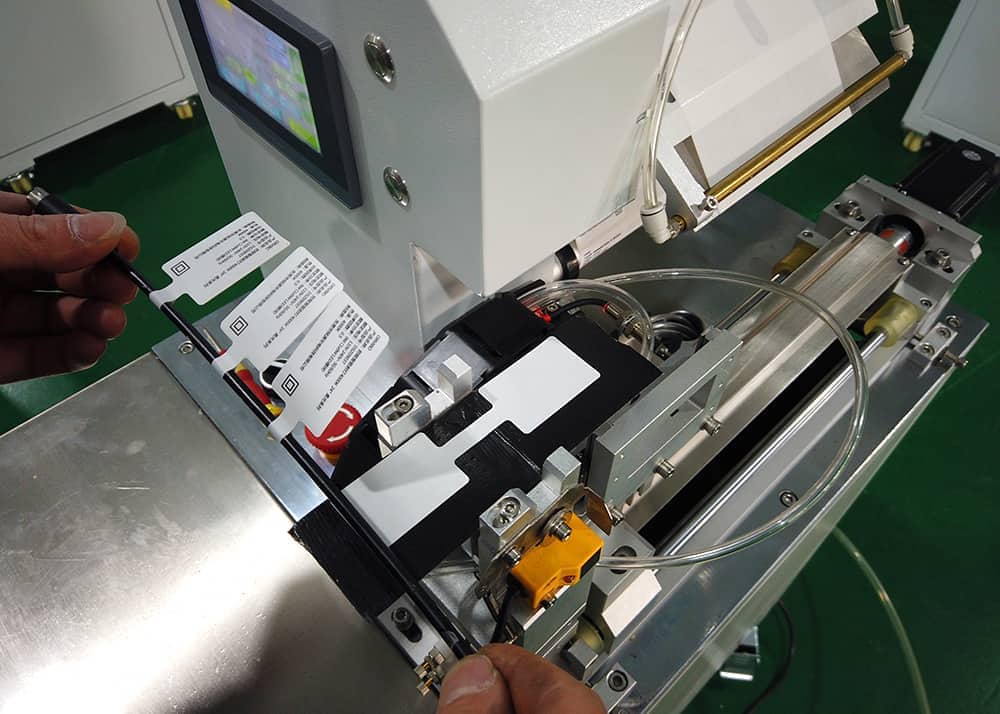

A tube labeling machine is designed to apply labels to cylindrical products, such as tubes used in cosmetics, pharmaceuticals, and food industries. These machines come in various forms, from manual tube labelers to fully automated tube labeling systems. Your choice depends on your production needs and budget.

Manual tube label machines are ideal for small businesses or startups with limited production. They are cost-effective and easy to operate, requiring minimal training. On the other hand, automated tube labeling machines are perfect for larger operations that need high-speed labeling and precision. These machines can handle large volumes of tubes with minimal human intervention, significantly boosting productivity.

Key Features to Consider

When choosing a tube labeler machine, it’s essential to look at specific features that can meet your production requirements. One crucial factor is the type of tubes you are labeling. Different machines are designed to handle various tube materials and sizes, so ensure the machine you choose is compatible with your products.

Another important aspect is the machine’s speed and accuracy. Automated tube labeling machines offer high-speed labeling with consistent precision, which is vital for maintaining product quality and meeting production deadlines. Additionally, look for machines with user-friendly interfaces and easy maintenance, as these features can save time and reduce operational costs.

Things to Pay Attention To:

Tubes are generally hollow, so it’s important to control the labeling gap during the labeling process. If the tube is solid, a smaller gap is fine because it won’t crush the tube. However, if the tube is hollow, even a slightly smaller calculated gap can potentially crush the tube.

Finding Reliable Tube Labeling Machine Suppliers

Selecting the right supplier for your tube labeling machine is as important as choosing the machine itself. Reputable tube labeling machine suppliers offer high-quality machines backed by excellent customer service and support. When evaluating suppliers, consider their experience in the industry, customer reviews, and the range of products they offer.

A good supplier will provide comprehensive training and support, ensuring your team can operate the machine efficiently. They should also offer maintenance services and spare parts to keep your machine running smoothly. Building a long-term relationship with a reliable supplier can lead to better deals and ongoing support for your business.

Balancing Cost and Quality

Cost is always a significant factor when investing in a tube labeling machine. While it’s tempting to go for the cheapest option, it’s essential to consider the long-term value of the machine. High-quality machines may have a higher upfront cost but offer better performance, durability, and lower maintenance costs over time.

Evaluate the tube labelling machine in terms of its total cost of ownership, which includes the initial purchase price, maintenance, and operational costs. A slightly more expensive machine with better features and reliability can save you money in the long run by reducing downtime and increasing productivity.

Ensuring Compliance and Quality Control

In industries like cosmetics and pharmaceuticals, compliance with labeling regulations is crucial. Your tube labeling machine should ensure that all labels are applied accurately and consistently, meeting industry standards. A reliable machine helps avoid labeling errors that could lead to regulatory issues or product recalls.

Quality control is another critical aspect. The right tube labeling machine will help maintain consistent label quality, enhancing your product’s appearance and brand reputation. Automated machines often come with built-in quality control features, such as sensors and cameras, to detect and correct labeling errors in real-time.

Conclusion

Choosing the right tube labeling machine involves considering your production needs, budget, and the type of tubes you are labeling. By investing in a high-quality machine and partnering with a reliable supplier, you can enhance your labeling efficiency and ensure consistent product quality. Remember, a good tube labeling machine is an investment in your business’s future success.